library(qcc)

cause.and.effect(cause=list(Measurements=c("Micrometers", "Microscopes", "Inspectors"),

Materials=c("Alloys", "Lubricants", "Suppliers"),

Personnel=c("Shifts", "Supervisors", "Training", "Operators"),

Environment=c("Condensation", "Moisture"),

Methods=c("Brake", "Engager", "Angle"),

Machines=c("Speed", "Lathes", "Bits", "Sockets")),

effect="Surface Flaws")DSC 3091- Advanced Statistics Applications I

Statistical quality control

Department of Statistics and Computer Science

Introduction

Quality is the degree to which products or services meet the needs of customers.

Common goals for quality professionals include reducing defect rates, manufacturing products within specifications, and standardizing delivery time.

Advantages of quality control

Reduction in production/inspection cost

Prior fault detection

Satisfaction of consumers

Effective utilisation of resources

The process of using statistical tools and techniques to monitor and manage product quality across various industries.

Can be conducted as

A part of production process,

A part of last-minute quality control check

A part of eventual check by quality control department

![]()

Methods of Quality Control

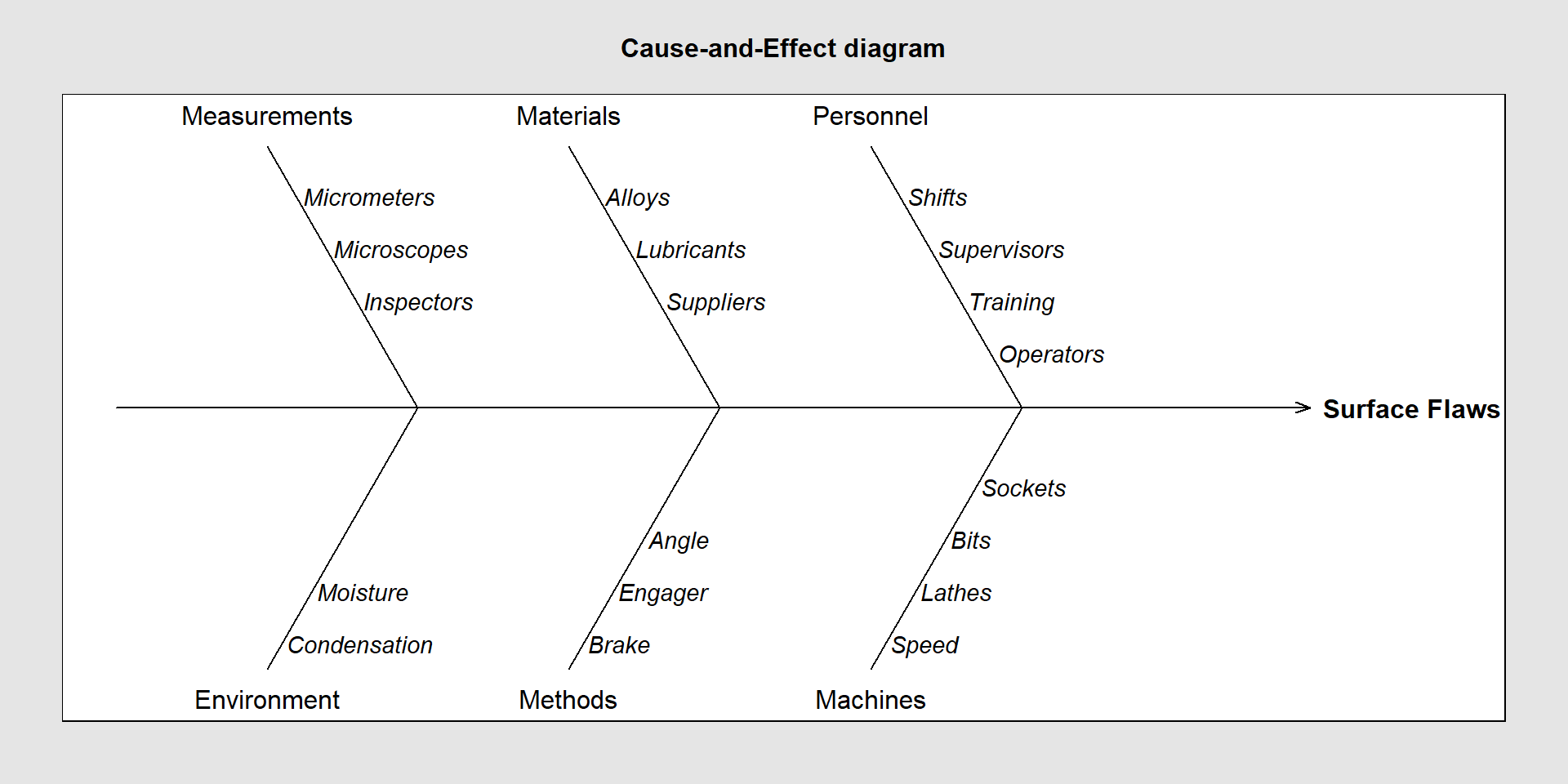

- Cause and effect diagrams

- Control charts

- Check sheet

- Histograms

- Pareto charts

- Scatter diagrams

- Stratification

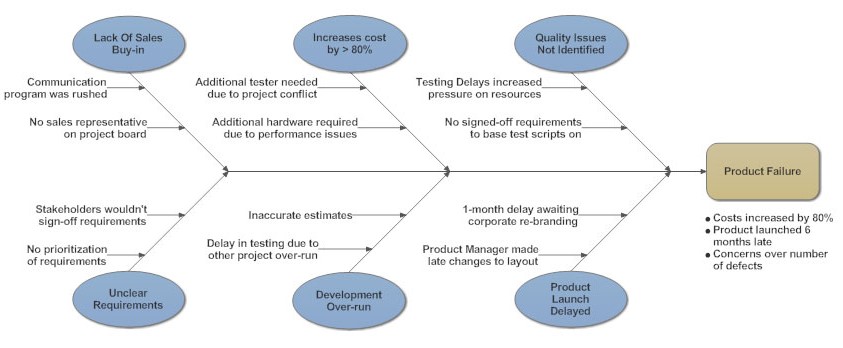

Cause and effect diagrams

is a visualization tool for categorizing the potential causes of a problem.

It can also be useful for showing relationships between contributing factors.

![]()

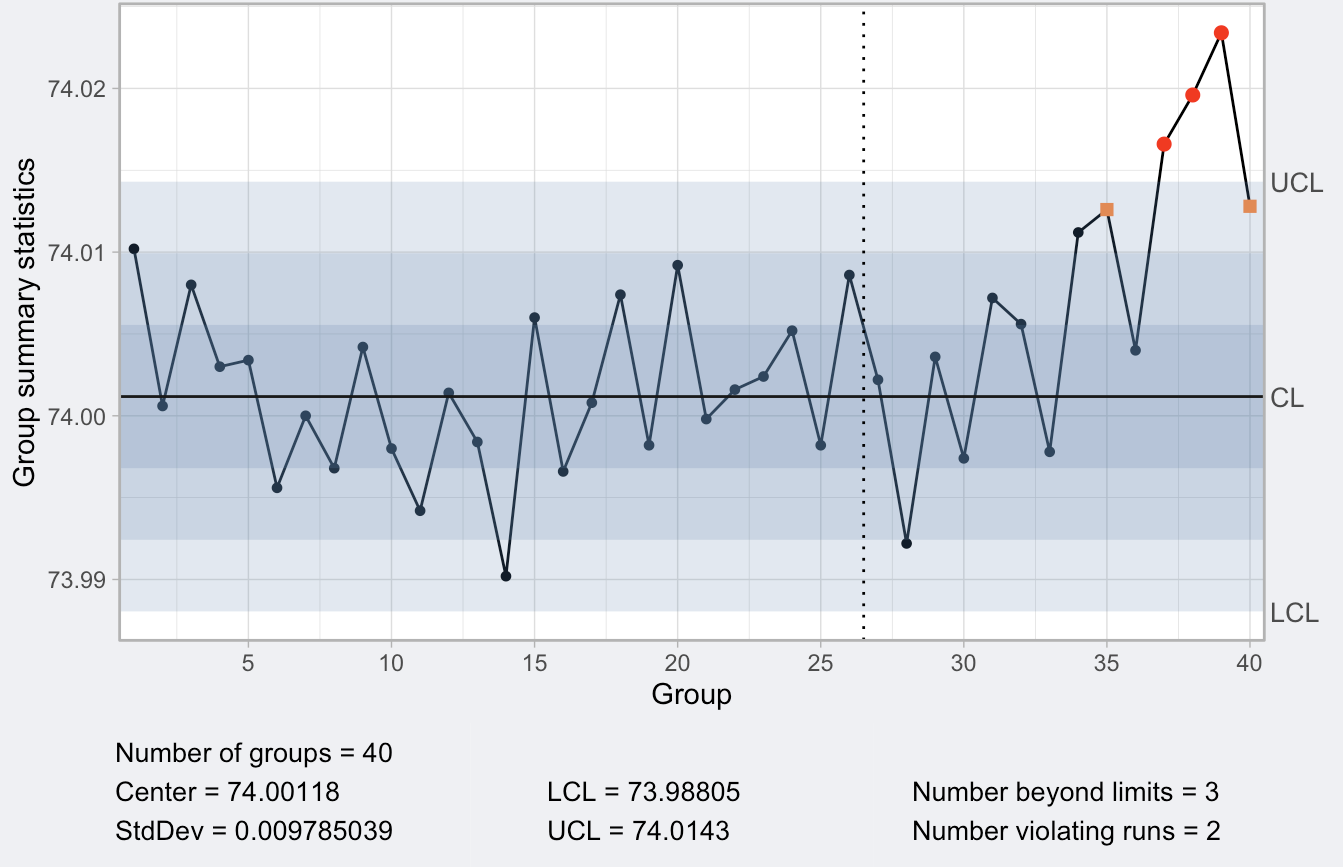

Control Charts

Unusual patterns in your data indicate the presence of special-cause variation.

Use control charts to detect special-cause variation and to assess process stability over time.

The center line is the average value of the quality statistic that you choose to assess.

If a process is in control, the points will vary randomly around the center line.

- The control limits are calculated based on the expected random variation in the process.

- The upper control limit (UCL) is 3 standard deviations above the center line.

The lower control limit (LCL) is 3 standard deviations below the center line.

If a process is in control, all points on the control chart are between the upper and lower control limits.

Chart Selection

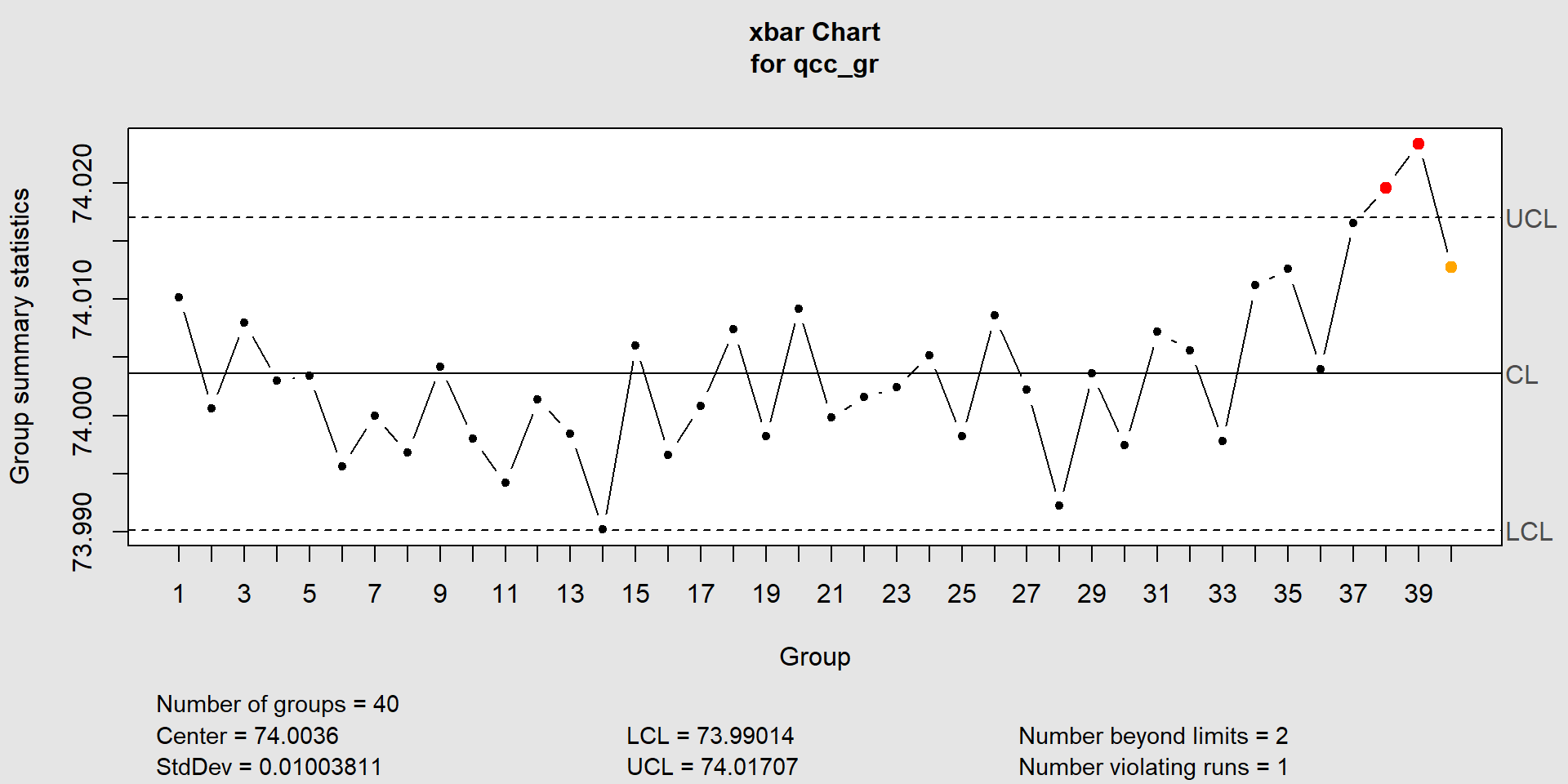

X-bar chart

library(qcc)

data("pistonrings")

attach(pistonrings)

qcc_gr <- qcc.groups(diameter, sample)

head(qcc_gr) [,1] [,2] [,3] [,4] [,5]

1 74.030 74.002 74.019 73.992 74.008

2 73.995 73.992 74.001 74.011 74.004

3 73.988 74.024 74.021 74.005 74.002

4 74.002 73.996 73.993 74.015 74.009

5 73.992 74.007 74.015 73.989 74.014

6 74.009 73.994 73.997 73.985 73.993

Nelson Rules for Control Charts

One point above UCL or below LCL

Two points above/below 2 sigma

Four out of five points above/below 1 sigma

Eight points in a row above/below the center line

Six points in a row ascending or descending (trend)

15 points in a row “hugging” the center line (between -1 and +1 sigma)

14 points in a row alternating up and down

Eight points in a row above 1 sigma or below -1 sigma

Exercise 1

The quality.csv file contains data about time taken to deliver some products of Western shipping center in Colombo. The manager of the Western shipping center obtained this dataset by randomly selecting 10 samples for 20 days. Using the data, determine whether the delivery process of the company is stable over time.

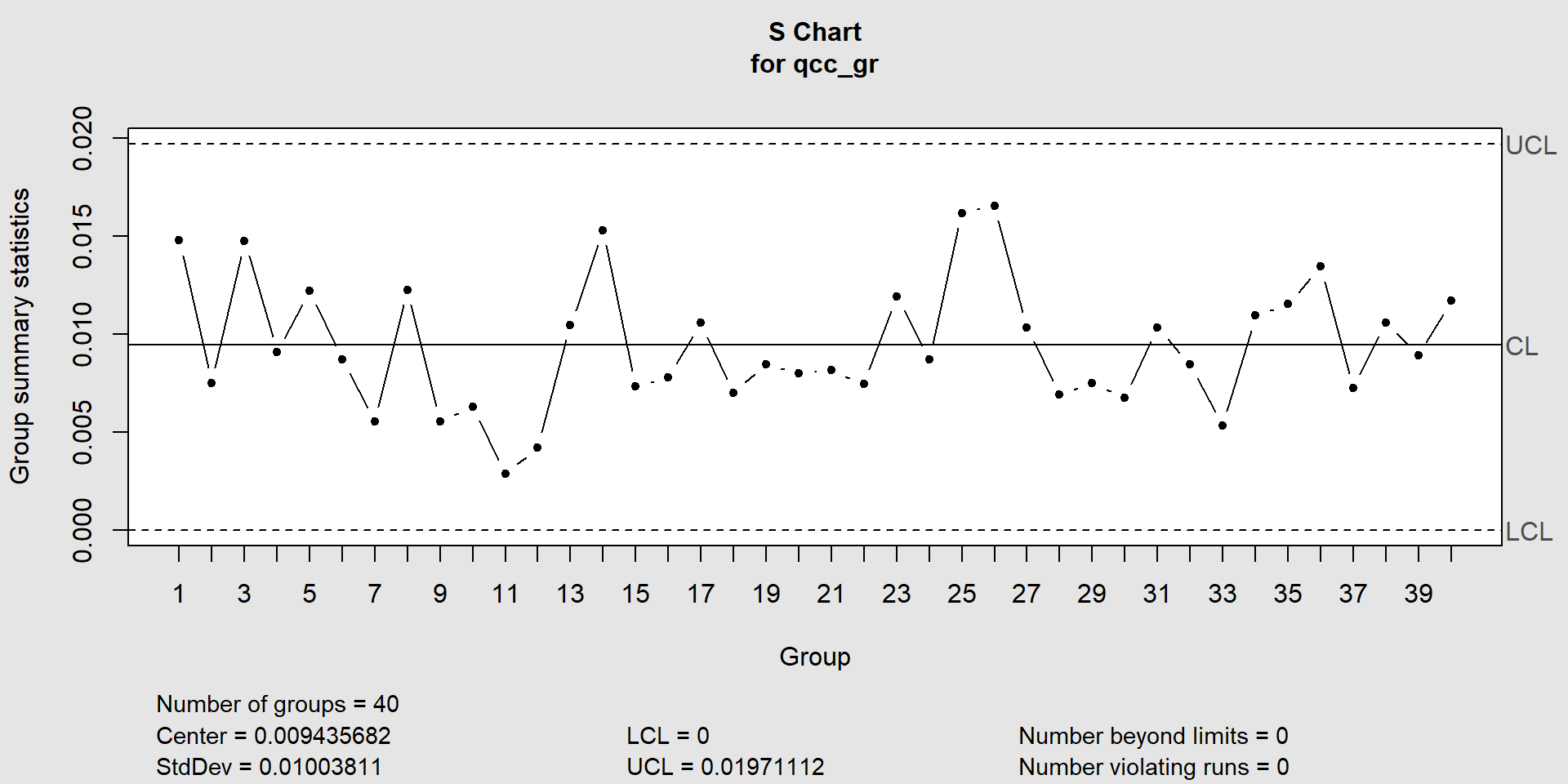

Create an S chart

- Use to assess the variability of the process.

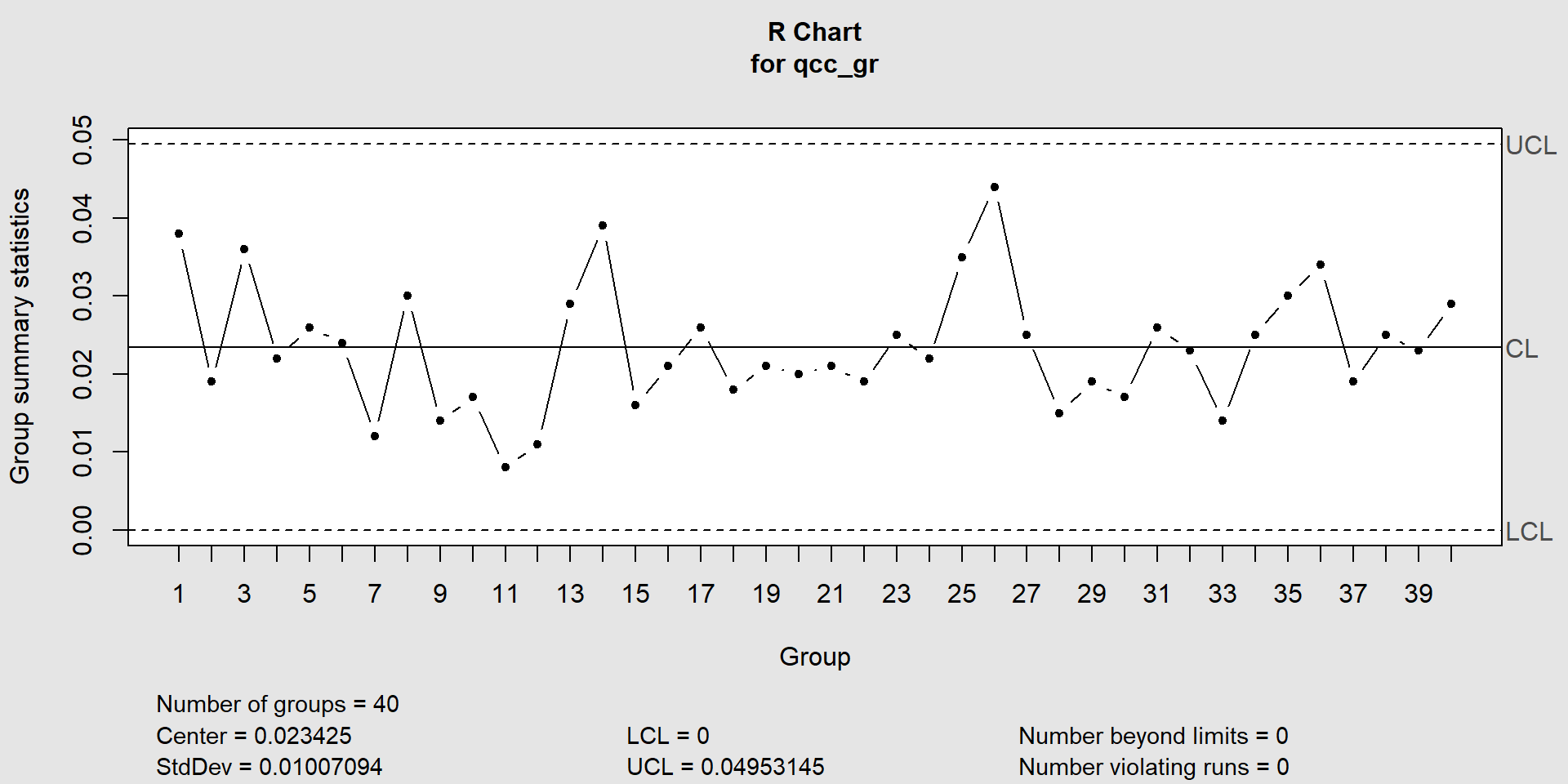

Create an R chart

- Use to assess the variability of the process with small samples.

Exercise 2

Using the same dataset considered in Exercise 1, determine whether the variability of the delivery process of the company is stable over time.

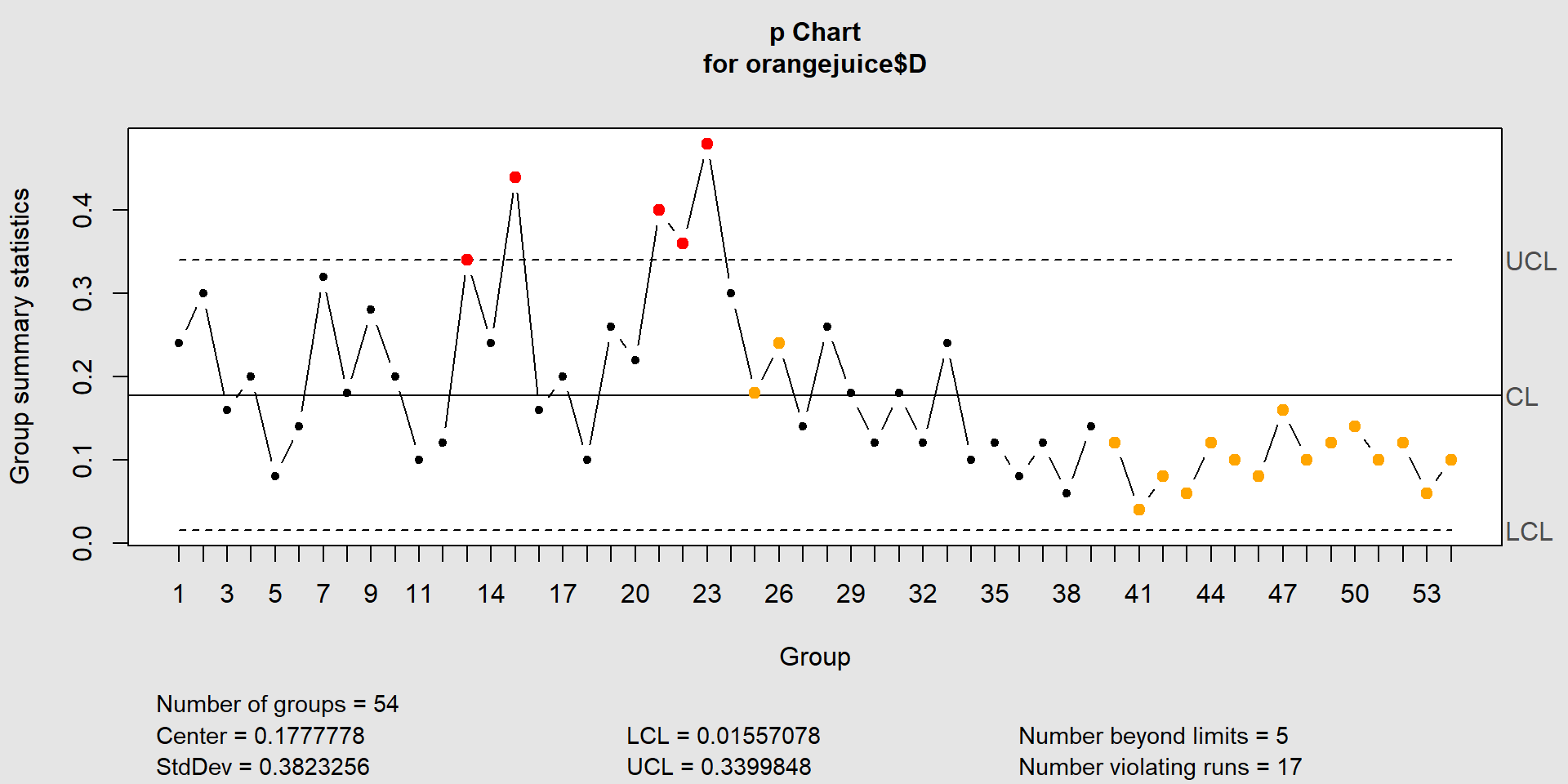

Discrete Measurements: p and np Charts

Process capability analysis

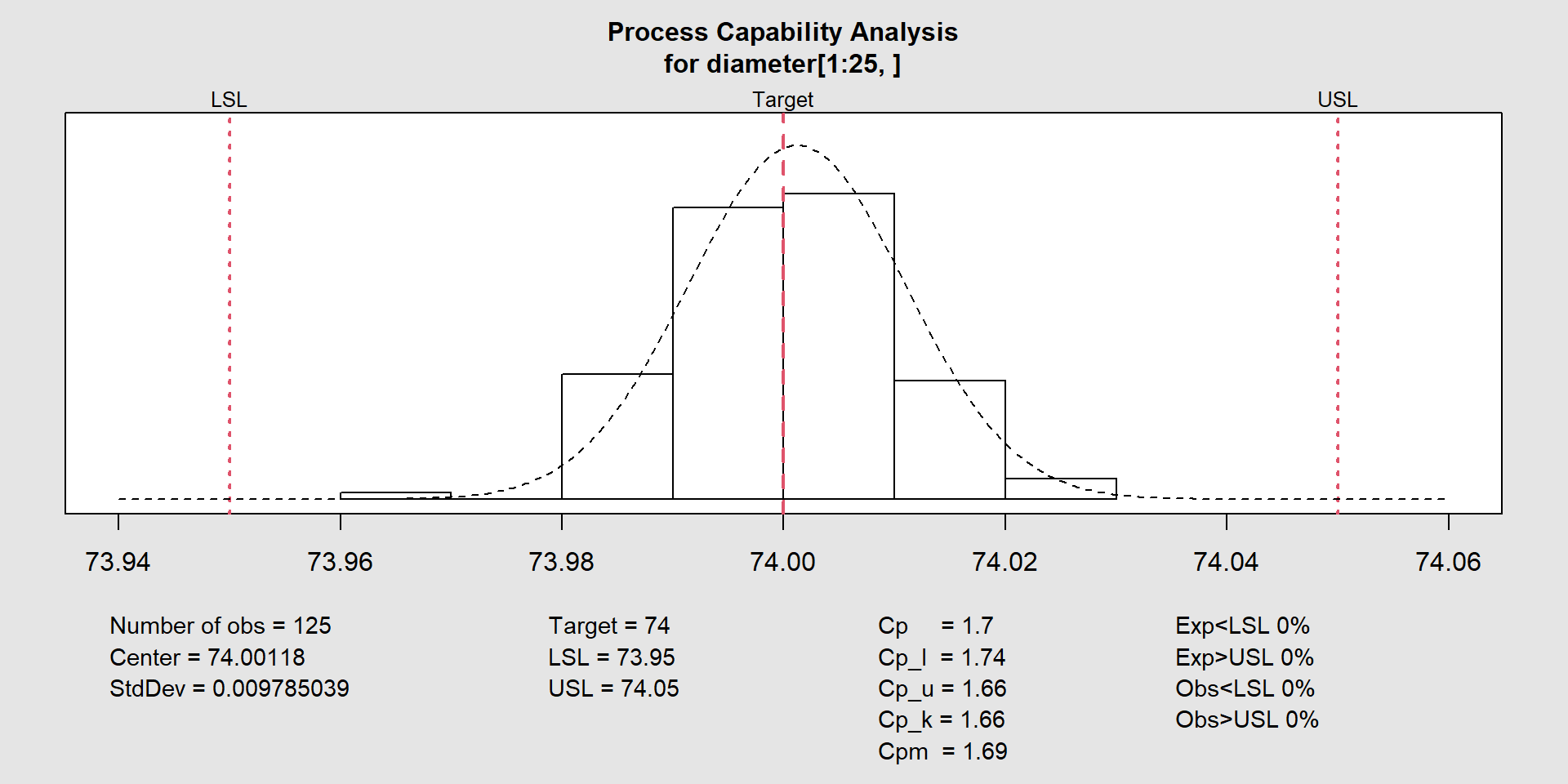

- Measure whether consumer specified upper and lower specification limits (LSL/USL) are compatible with process control limits (LCL/UCL)

data(pistonrings)

attach(pistonrings)

diameter <- qcc.groups(diameter, sample)

q <- qcc(diameter[1:25,], type="xbar", nsigmas=3, plot=FALSE)

process.capability(q, spec.limits=c(73.95,74.05))

Process Capability Analysis

Call:

process.capability(object = q, spec.limits = c(73.95, 74.05))

Number of obs = 125 Target = 74

Center = 74 LSL = 73.95

StdDev = 0.009785 USL = 74.05

Capability indices:

Value 2.5% 97.5%

Cp 1.703 1.491 1.915

Cp_l 1.743 1.555 1.932

Cp_u 1.663 1.483 1.844

Cp_k 1.663 1.448 1.878

Cpm 1.691 1.480 1.902

Exp<LSL 0% Obs<LSL 0%

Exp>USL 0% Obs>USL 0%

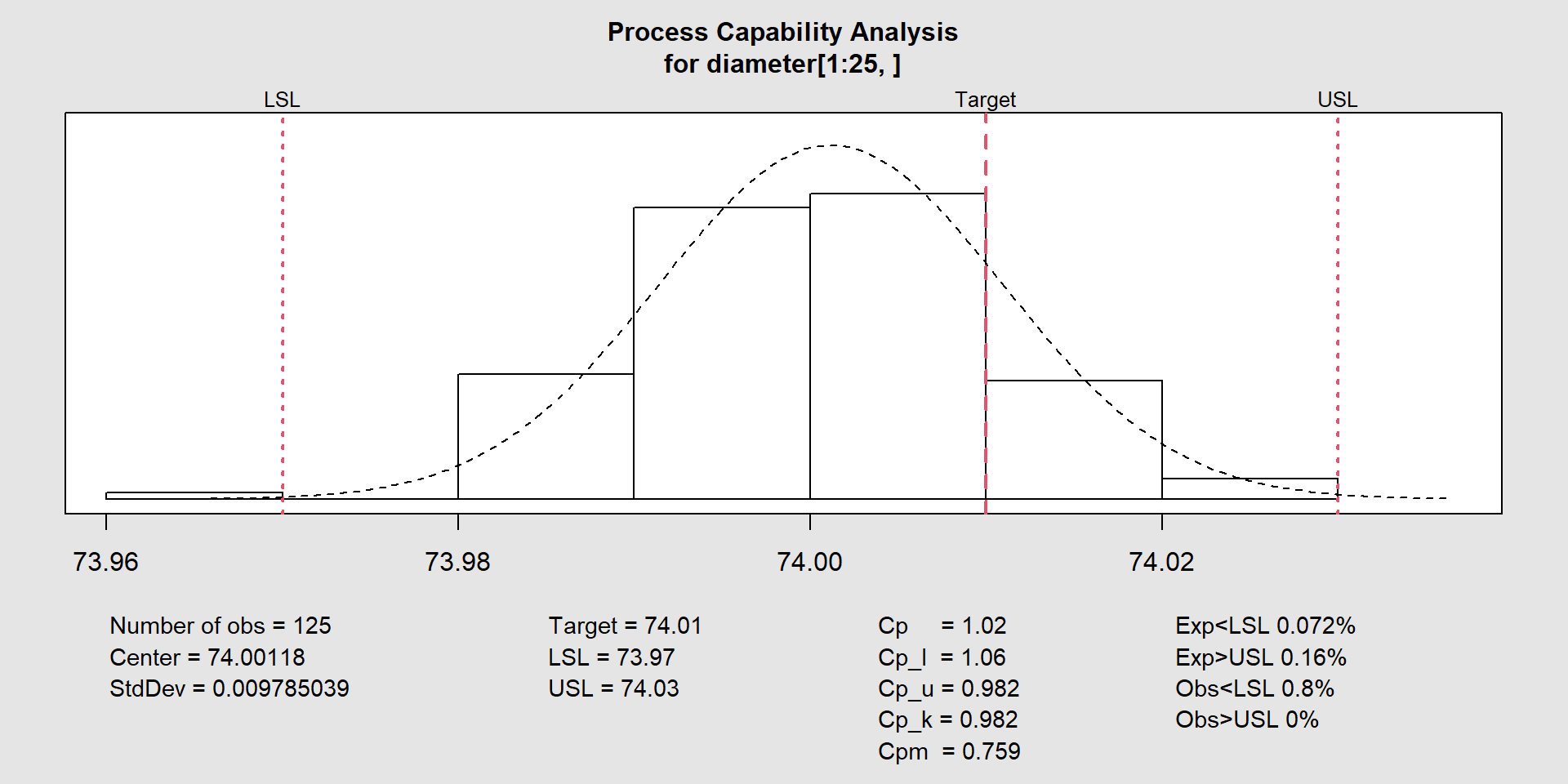

Process Capability Analysis

Call:

process.capability(object = q, spec.limits = c(73.97, 74.03), target = 74.01)

Number of obs = 125 Target = 74.01

Center = 74 LSL = 73.97

StdDev = 0.009785 USL = 74.03

Capability indices:

Value 2.5% 97.5%

Cp 1.0220 0.8948 1.1489

Cp_l 1.0620 0.9407 1.1833

Cp_u 0.9819 0.8682 1.0956

Cp_k 0.9819 0.8464 1.1174

Cpm 0.7589 0.6458 0.8719

Exp<LSL 0.072% Obs<LSL 0.8%

Exp>USL 0.16% Obs>USL 0%

Cp and Cpk Indices

Cp (Process Capability Ratio): measure related to the spread of a process.

Cpk (Process Capability Index): measure related to the centerness of a process.

Centered processes are analyzed based on their Cp ratio while non-centered processes are analyzed based on their Cpk index.

Exercise 3

Using the data in quality.csv, perform a capability analysis to determine whether the delivery process is within specification limits (LSL=1.5,USL=5) and produces acceptable delivery times.